Our Department

Virtual open day

Discover what life as a chemical engineering student is like with our virtual open day tour.

Why study here?

Find out why Manchester is the perfect place to undertake a chemical engineering degree.

Careers and employability

A degree from the Department will open up opportunities in a wide range of industries.

Latest news

Read more newsResearch

Themes

Our research concentrates on six main areas, with a strong focus on creating a sustainable future.

Impact

Our research encourages sustainability throughout society and industry in many different ways.

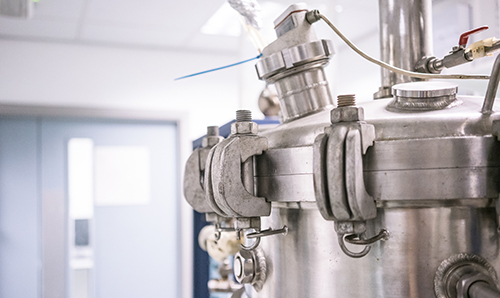

Facilities

Explore the Department's outstanding facilities, including the £12 million James Chadwick Building.

Connect

Business engagement

From collaborative projects to student sponsorships, business relationships are important to us.

Open days

Meet our staff and find out more about our courses by attending one of our open days.

Social responsibility

Social values are integral to the work of the Department and we're proud to hold an Athena SWAN award.