Multi-scale modelling

Our researchers

Researchers in this group develop and use modelling and simulation tools to addresses major research challenges, from the fundamental understanding of novel phenomena at atomic, molecular, meso, micro and macroscopic levels, to the prediction of industrially-relevant fluid properties and equipment performance.

This theme brings together a multidisciplinary team to study systems of both fundamental scientific importance and of practical relevance to the chemical industry. Our tools include quantum mechanical methods, molecular dynamics, Monte Carlo simulations, coarse-grained simulations, dissipative particle dynamics, lattice Boltzmann, computational fluid dynamics and mathematical theory.

We complement and validate our predictions with experimentally measured properties, using materials characterisation techniques (gas adsorption, microscopy etc) and a wide range of process analytics tools (tomography, rheometry, particle sizing etc).

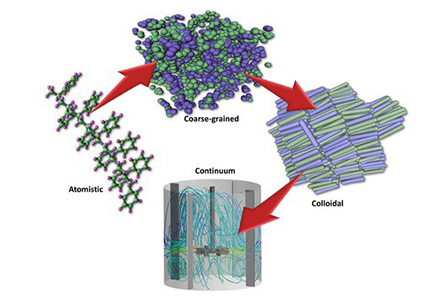

As an example of the techniques we use, let us consider a polymeric system. Depending on the application, we can look at polymers in terms of the motions of the constituent atoms, or we can regard the polymer as being made up of coarse-grained units, each unit containing tens of atoms, or we can regard aggregates of polymers as effective, colloidal particles, or as a continuous flow in a device.

There are three main areas of work that our researchers focus on: soft matter; fluids at surfaces, in confinement and porous materials; and modelling and simulation.

Fluids at surfaces, in confinement and in porous materials

Solid surfaces can significantly influence the behaviour of fluids. These effects are relevant in a number of industrial applications, from adsorption in porous materials, membrane separation and catalyst performance to the development of microfluidic devices.

Our efforts in this area include:

- the development of virtual models of porous material so as to understand how the packing of molecules creates different porous geometries;

- the modelling of how surface chemistry affects the behaviour of adsorbed and confined fluids;

- the modelling of fluid flow properties in porous media and microfluidic devices.

Modelling and simulation - methods development

Incorporating the correct physics in the description of a system is essential for a meaningful model. This can be challenging in complex systems where relevant phenomena occurs at multiple length scales. Among the group activities are new developments in:

- approaches to discover catalytic pathways using ab initio techniques;

- hybrid models for the multi-scale simulation of soft matter;

- theories of liquids, liquid crystals and emulsions;

- dynamic Monte Carlo techniques.

Soft matter - from fundamentals to manufacturing

Liquids, colloids, gels, foams, liquid crystals and polymers are all forms of soft matter. As well as their many industrial applications (paints, lubricants and shampoos to name just three), their science is fascinating and their formulation challenging. We study the structural and dynamical properties of these systems with a combination of computer simulation (molecular dynamics, Monte Carlo and coarse-grained methodologies) and mathematical theory. We are also interested in understanding the rheological behaviour of complex mixtures in industrial mixing equipment and developing direct numerical simulation (DNS) computational fluid dynamics (CFD) modelling approaches to simulate the non-Newtonian behaviour of soft matter.